Factory automation systems are designed to improve efficiency and productivity in manufacturing environments. By automating tasks that are traditionally performed by human workers, factory automation systems can help reduce production costs and improve quality control.

In addition, a factory automation system can help to improve workplace safety by reducing the need for workers to perform hazardous tasks.

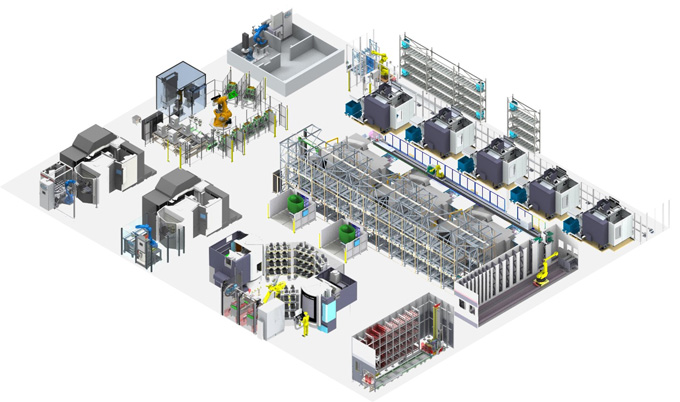

Image Source:- Google

Automation systems are becoming increasingly popular in factories as a means to improve efficiency and productivity. There are many different types of automation systems available, each with its own advantages and disadvantages. It is important to choose the right type of system for your particular factory and application.

The following tips will help you ensure that your automation system is efficient and productive:

1. Define your objectives clearly before selecting an automation system. Consider what you want to achieve with the system and how it will fit into your overall production process.

2. Do your research and compare different types of systems before making a purchase. Make sure you understand the capabilities and limitations of each type of system before making a decision.

3. Work closely with the supplier of your chosen system to ensure it is installed correctly and integrated seamlessly into your existing production process.

4. Train your staff on how to use the new system properly. Make sure they understand its capabilities and limitations and know how to operate it safely and effectively.

5. Monitor the performance of the system regularly, and make adjustments as necessary to ensure it continues to meet your needs efficiently and productively.